Gibbs and Associates, a Cimatron company, announced that Rodney Babcock, president and owner of Next Intent, will deliver a presentation in the Gibbs and Associates booth at IMTS 2014.

Gibbs and Associates, a Cimatron company, announced that Rodney Babcock, president and owner of Next Intent, will deliver a presentation in the Gibbs and Associates booth at IMTS 2014.

Mr. Babcock has 35 years’ experience in manufacturing, including manual and computerized CNC programming and machining. He will discuss national space exploration projects and his company’s participation in the manufacturing, assembly and testing of specific components for these projects. Specializing in the design, machining and assembly of components for aerospace, defense, and national laboratories.

Next Intent is located in San Luis Obispo, California. Mr. Babcock’s presentation will be on Tuesday, September 9 – Thursday, September 11th daily at 10:00 a.m. and at 2:00 p.m., in the Gibbs and Associates Booth, E-3310.

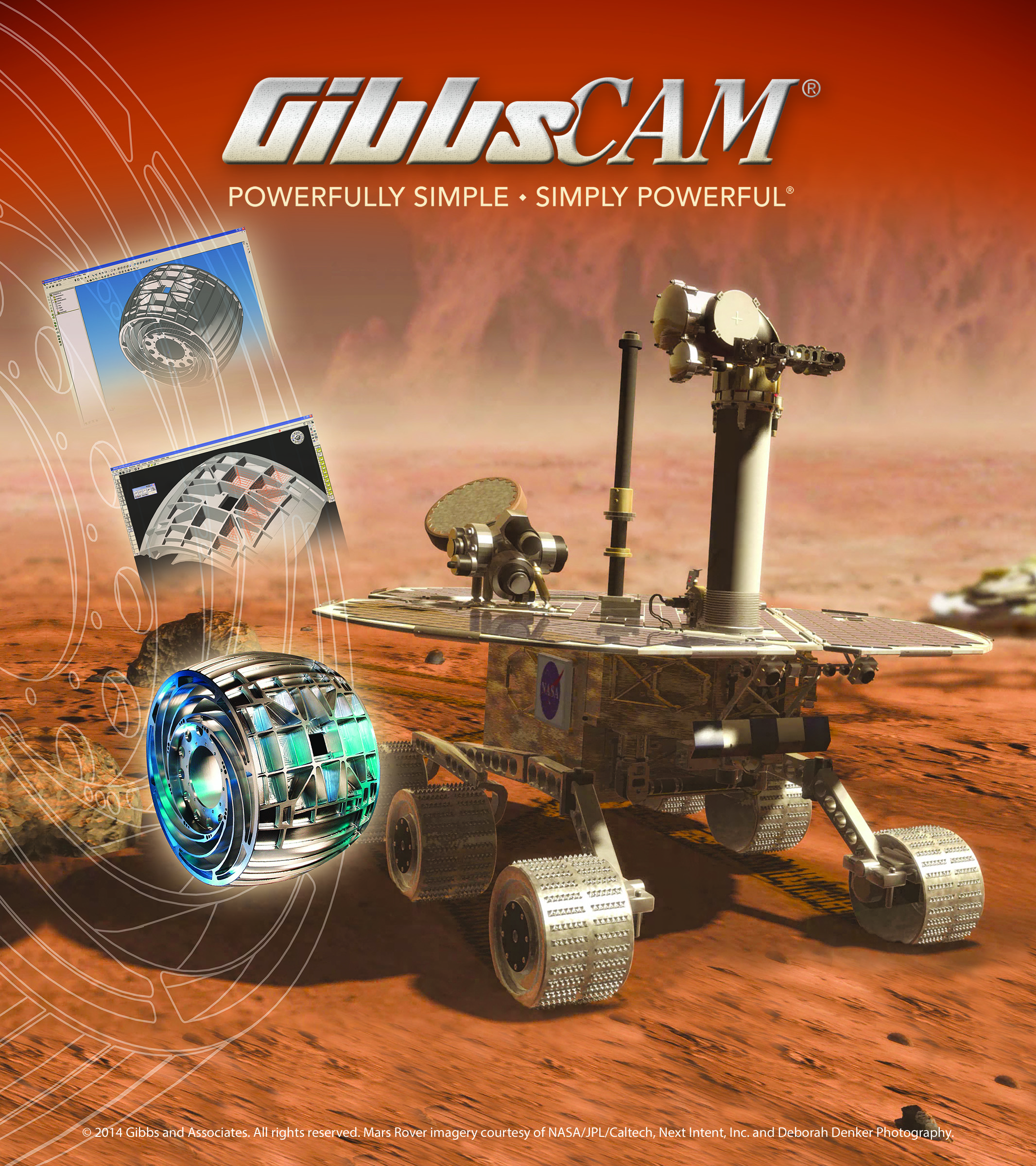

Next Intent has been a Gibbs customer since its founding by Mr. Babcock, in 1996, using GibbsCAM to program all of its milling and turning machines. The company has been a user of GibbsCAM solids and 5-axis machining since 2000. Among its various projects, Next Intent has provided components for the Mars Exploration Rovers Spirit and Opportunity, the Mars Science Laboratory Rover Curiosity, the James Webb Space Telescope, the National Ignition Facility (operated by the Lawrence Livermore National Laboratory), and the Antares Rocket, developed for missions to the International Space Station.

Gibbs and Associates will also introduce GibbsCAM UKM (Universal Kinematic Machine), the brand-new engine behind the upcoming release of GibbsCAM 2015, at IMTS 2014.

GibbsCAM 2015 with new UKM engine provides highly accurate machine simulation on machines of virtually any configuration.

GibbsCAM UKM is a complete re-engineering of the CAM engine and how it relates to machine definitions and machine tools, blurring the line between the definition of mills and lathes.

Bill Gibbs, CEO and President of Gibbs and Associates explains: “With GibbsCAM UKM, users can program and accurately simulate virtually any machine today and even machines that haven’t been invented yet.”

The benefits of the GibbsCAM UKM engine extend throughout the entire product line, not just those areas relating to complex machines. Machine simulation and post processors are built on the same kinematic model, optimizing the programmer’s time and ensuring complete accuracy.

The new UKM architecture is backward compatible, so current post processors and machine simulation models for GibbsCAM will continue to provide a return on investment. In addition, customers will be able to program and simulate the most complex machines on the market, including machines from Bumotec, Citizen, DMG MORI, Doosan, Matsuura, Mazak, Nakamura-Tome, Okuma, Star, Tornos, Willemin-Macodel, and many others.

Significant changes have been made to the tooling functionality of GibbsCAM 2015. In addition to new tool types being added (Barrel, Dovetail, Convex Tip, E-style ISO insert, and tools defined by solids), GibbsCAM now has dynamic 3D viewing of tools and tool-holders in the tool dialog, allowing users to accurately visualize the tools they are selecing for the job.

An entire new category of tooling has been added called Intermediate Tooling. This allows for items that are neither tools nor fixed parts of the machine, such as fixtures (chucks, tailstocks, steadyrests) and toolblocks (adapter blocks, holders for toolholders, and the like). Programmers can create libraries of toolblocks to easily setup complex machines, and can share those libraries across different parts, saving time and reducing errors.

GibbsCAM 2015 has significant improvements throughout the product line, from geometry creation to toolpath strategies, including additional High Speed Machining (HSM) strategies. New functionality has been added to aid in the importing and machining of hole features. Holes are now treated as fully associative features of solid bodies, including those imported from SolidWorks, Solid Edge, Autodesk Inventor, or CATIA V5. Compound holes (holes with multiple segments that might each be tapered or threaded) are now supported as well. New Geometry tools include improved spline editing and contour tracing capabilities. Improvements to machining include new Adaptive Roughing capabilities, pre-drilling and background processing for VoluMill, and many new capabilities for the Tombstone Management System, which has long been recognized as the most comprehensive software for programming parts on a tombstone.

The GibbsCAM (and CimatronE) exhibit is in Booth E-3310 of the Controls and CAD-CAM Pavilion.

For more information, visit www.gibbscam.com.