Röhm Products of America recently redesigned its RKE NC-Compact Vice clamping system to include several technical improvements for better functioning in CNC machining centres.

Röhm Products of America recently redesigned its RKE NC-Compact Vice clamping system to include several technical improvements for better functioning in CNC machining centres.

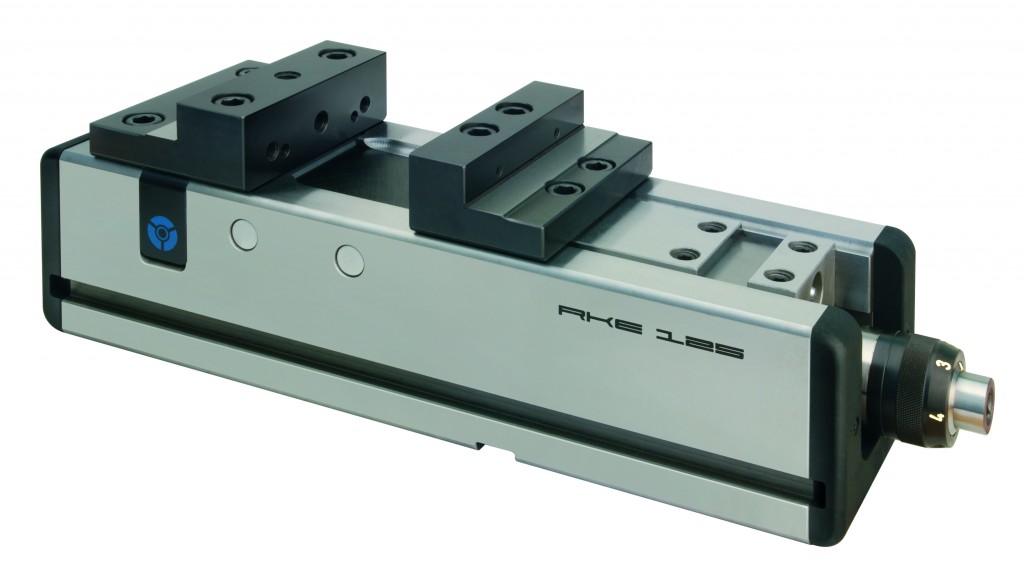

Featuring a steel body with its contact surfaces and guides hardened and ground on all sides, the RKE NC-Compact Vice now offers better chip discharge with fewer interfering contours.

Furthermore, protective caps and dirt protectors prevent chips from penetrating the inside of the vice body. A central grease nipple sits next to the adjustable drive spindle for easy accessibility and simple lubrication of the spindle threads and all guides.

Available in four different jaw widths – 3.6, 4.9, 6.3 and 7.9 – the RKE NC-Compact Vice provides for horizontal, lateral or vertical mounting options. Thread connections allow use of all Röhm flat-clamping jaws within the 4.9 and 6.3 width sizes.

Röhms product portfolio encompasses drill chucks, live centres, lathe chucks, vices, automation technology, power chuck technology, mandrels, tool clamping systems and customized solutions for turning, milling, drilling and grinding applications.

www.rohm-products.com