MC Machinery Systems, Inc., wholly owned by Mitsubishi Corp., has partnered with Matsuura Machinery Corporation to introduce the new LUMEX Avance-25 metal laser sintering hybrid milling machine to the North American market.

MC Machinery Systems, Inc., wholly owned by Mitsubishi Corp., has partnered with Matsuura Machinery Corporation to introduce the new LUMEX Avance-25 metal laser sintering hybrid milling machine to the North American market.

The additive manufacturing industry is becoming a lot more popular in North America. Meanwhile, Matsuura’s laser sintering hybrid milling machines have been sold specifically in the die and mold industry in Japan and Asia.

The mold makers know us and know our people, and we’re excited to be able to offer them this innovative new technology, says Nick Giannotte, VP, EDM/Milling/Waterjet.

We have an experienced dealer network, many of whom boast 40 per cent market share in their regions. They have relationships with the markets, not to mention the more than 10,000 person-strong customer base we have at MC Machinery.

Sales expansion won’t be limited to mold and die; both companies are also targeting the aircraft industry, in which lightweight parts will add fuel efficiency, and the medical industry, which requires custom-made bones and implants.

The machine will serve medical, automotive, aerospace, tool/die, and job shop industries. Technical centres located in Chicago, Los Angeles, Toronto, and New Jersey are equipped with demo facilities and staff to serve the North American market and demonstrate the LUMEX Avance-25’s unique capabilities.

The machine:

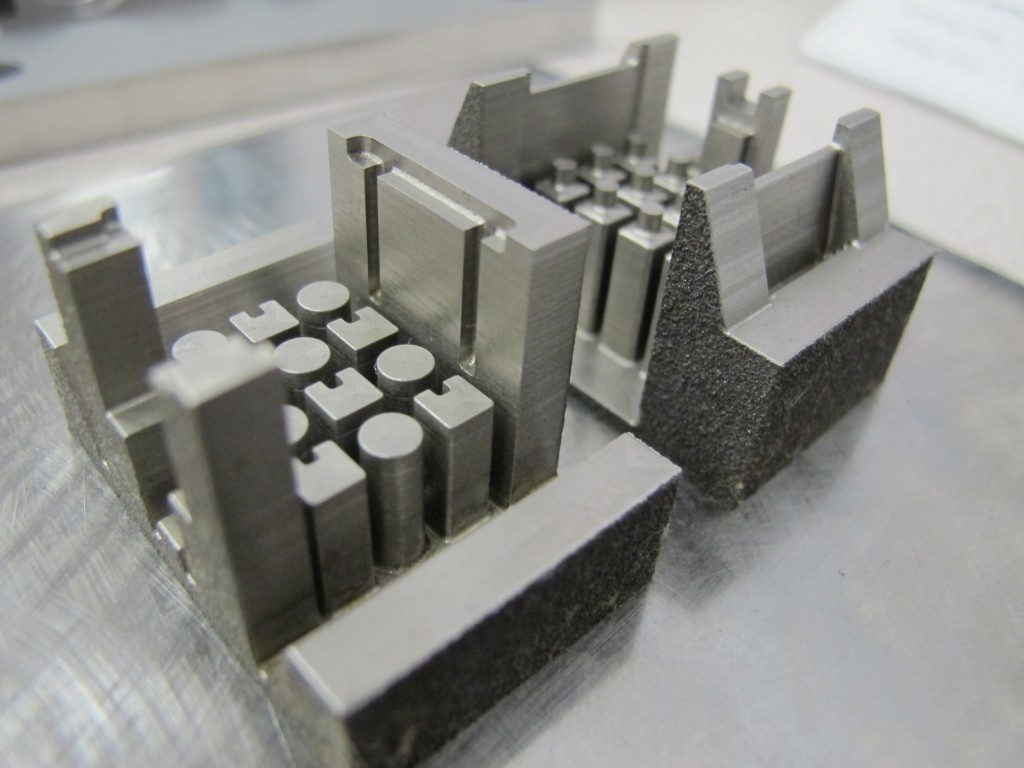

The machine enables production of complicated parts through total manufacturing by digital engineering, using 3D data. It achieves the highest accuracy in part fabrication since metal powders are melted and sintered via laser, while surfaces are precisely milled at high speeds.

metal laser sintering and milling technologies working in concert will allow engineers to think outside the box and create unique ideas, potentially triggering a departure from conventional manufacturing.

Die and mold application:

Dies and molds with very complex geometries can be fabricated in one piece with high accuracy, shortening lead time and reducing manufacturing costs to a half or even a third of conventional methods. Also, 3D cooling channels can be incorporated into molds in the single set-up, thereby increasing cooling efficiency and enabling high-cycle injection molding with better than ever quality and precision, reducing costs and improving efficiency.

Application to parts production:

Differentiated original parts production with internal structures, thus far considered impossible, are feasible on this machine. What’s more, this metal laser sintering hybrid milling machine is capable of quick turn production of custom parts, whether prototypes or small production run parts.

For more information visit:www.mitsubishi-world.com