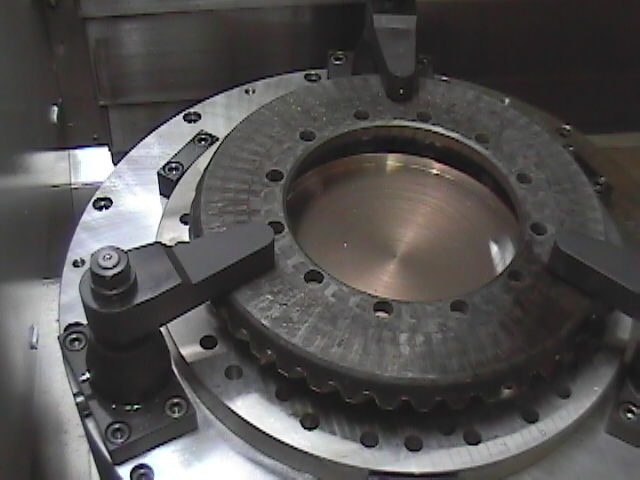

Powerhold has expanded the size range of their 900 Series Swing Clamp style chucks to cover applications requiring up to a 24” size chuck.

base models are now offered in 2 or 3 clamp styles in 7”, 10”, 12”, 15”, 18” and 24” models.

Powerhold 900 series chucks are drawbar actuated, using a standard hydraulic or pneumatic lathe cylinder.

The most common models include a standard part rest plate using a diamond pin for radial part orientation, Part rests can be provided by Powerhold or supplied by the customer. Special designed chucks can include centering collets, springloaded rest pins, and face mounted counterweights can be provided for non-symmetric parts.

For more challenging parts, custom positions for clamp arm assemblies, including clamping through the part ID can be offered. Optional air-sensing part-/confirm/iation, and thru-spindle coolant can be included in most custom designs.

Powerhold can integrate the coolant and/or air feed using your existing hydraulic cylinder, or provide a complete spindle package including our Gamet VX Series Hydraulic thru-hole actuators.

Swing clamp chucks are used in many automotive applications including a wide range of transmission, axle and brake parts, but are ideal for many industries for production application wher odd part geometry, varying part clamping heights, or delicate thin-wall parts must be gripped.

Powerhold has over 55 years of experience in manufacturer of custom collet, diaphragm, clamping disc and specialty jaw chucks.

www.powerholdinc.com