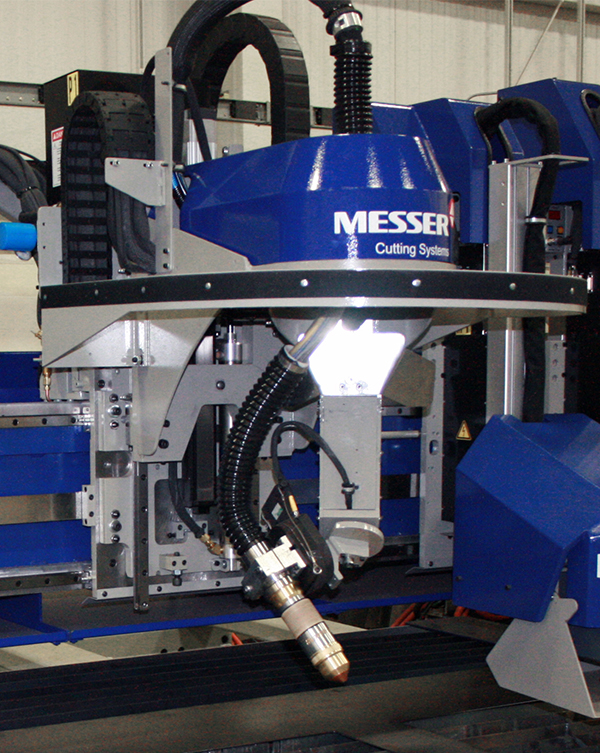

Messer Cutting Systems has announced the release of their new Deltae plasma rotator.

Messer Cutting Systems has announced the release of their new Deltae plasma rotator.

The launch is scheduled for the 2013, FABTECH show in Chicago. North Americas largest, metal forming, fabricating, welding and finishing event. With over 35,000 attendees and 1500 exhibitors this provides an excellent platform for the market launch of the Deltae rotator.

The Deltae features new robust compact design, drives, along with a new Messer designed torch holder assembly, coupled with our OmniBevel software, creates the best cut parts available on the market. The Deltae will be featured on the Titan III cutting machine.

Messer is also promoting two other new products; a Telesis Pinstamp for plate marking, and QR reader program to assist in maintenance.

Their focus at the FABTECH show will be to give new and existing customers a hands on approach with live demonstrations of steel plate marking and cutting. Also demonstrated will be the plate alignment/hole detection video camera on Messers other cutting machine the EdgeMax.

We anticipate an excellent market welcome with the new Deltae , says Joerg Toberna Director of Marketing.

More information can be found online at: www.messer-cs.com

Messer Cutting Systems headquartered in Menomonee Falls, Wisconsin. Their machines use advanced plasma, oxyfuel, and laser, drilling cutting tools to cut shapes from mild steel, aluminum and stainless steel plate.