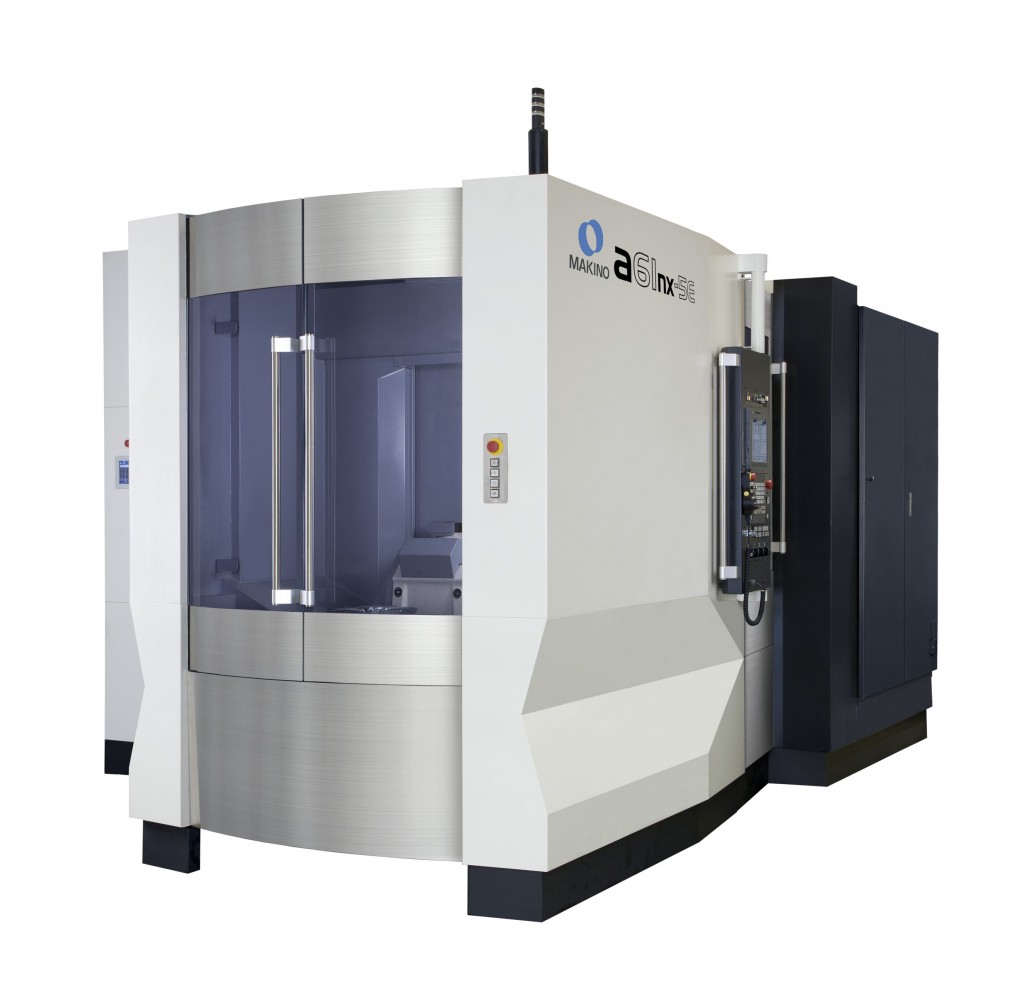

Makino has introduced their a61nx-5E a “right-sized” 5-axis horizontal machining centre for complex aluminum aerospace parts.

Makino has introduced their a61nx-5E a “right-sized” 5-axis horizontal machining centre for complex aluminum aerospace parts.

As aerospace manufacturing continues to ramp up in North America, the a61nx-5E offers an appropriately sized design for small components featuring 3-D contours.

However, it does so without compromising the spindle performance and 5-axis capabilities of larger aerospace machines.

“The a61nx-5E features the same robust design and proven reliability of our smaller nx-Series horizontal machining centres, but with the added speed and performance of our larger MAG-Series machines,” said David Ward, Makino horizontal product line manager.

RELATED: Makino releases new horizontal machining centres for medical manufacturing

“This machine differentiates itself from other similar 5-axis horizontal platforms with an innovative pallet-change system, advanced twin-direct-drive rotary table design, and availability of a high-power 24,000-rpm spindle.

The result is a highly productive, right-sized solution that can provide up to 310 cubic inches of metal removal per minute.”

The a61nx-5E provides enhanced rigidity through a three-point bed casting and tiered column structure. It has X-, Y- and Z-axis travels of 730 mm (28.7 inches), 730 mm and 680 mm (26.8 inches), respectively.

A closed-loop thermal management system ensures reliability and accuracy by removing heat generated by the large direct-drive rotary table motors.

The a61nx-5E also uses the same tool magazines as the nx-Series of machines with a ring style ATC60 as standard. Optional matrix magazines with capacities of 133, 218 or 313 are available options.

For those companies handling high-performance, high-volume aluminum machining, the a61nx-5E has the option for the new 24,000-rpm high-performance core-cooled spindle.

www.makino.com