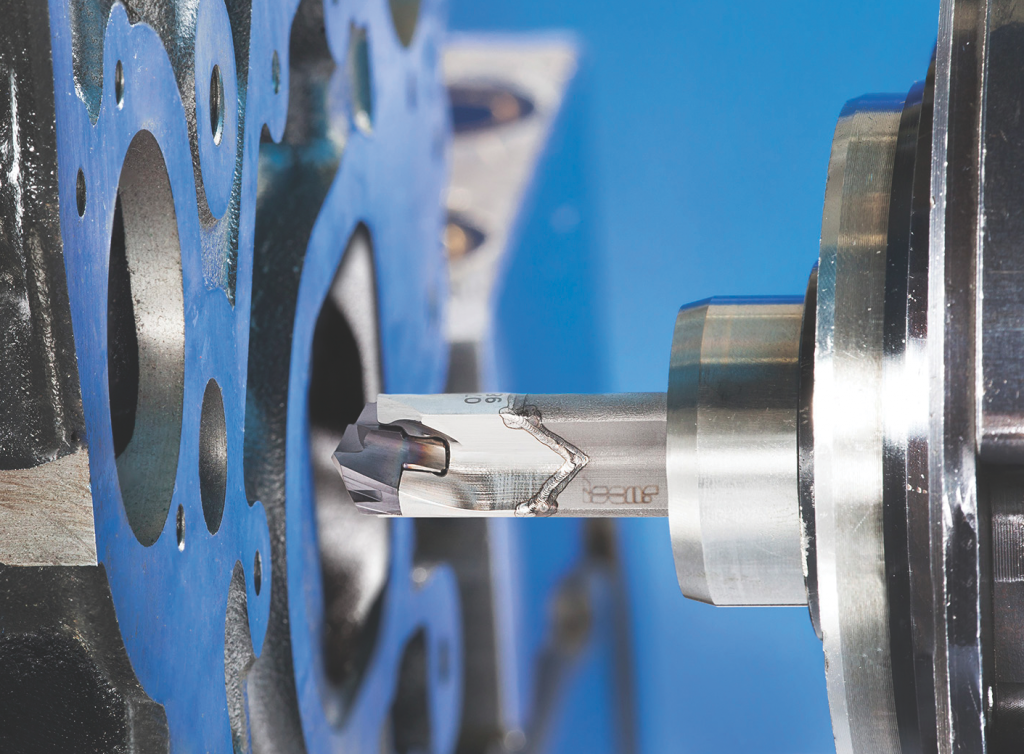

Iscars new Sumogun drill line. Click to enlarge. (Photo: Iscar)

At the May 7 launch of Iscar’s new IQ Products line, company CEO Jacob Harpaz waxed philosophic about the cutting tools trade before a crowd of shop owners and suppliers gathered in the RBC Theatre at Mississauga, Ontario’s Living Arts Centre.

New tools and inserts are “not something [created] overnight,” observed Harpaz, who compared the arrival of such products to the arrival of a newborn baby.

Like a proud Papa, Harpaz led a slide presentation that highlighted the latest the Israeli cutting tool giant had to offer.

Among other new products he introduced the Dove IQ Turn clamping system for tools and inserts. The system can firmly hold two-sided inserts with double negative prism flanks. A dovetail pocket and insert prismatic flanks prevent the insert from being lifted by cutting forces. Three insert geometries with prismatic flanks are available: WOMG- R3P-IQ, COMG-R3P-IQ and SOMG-R3P-IQ.

The Penta IQ Grip line of pentagonal inserts with five cutting edges was also cited by Harpaz. The line offers deeper grooving and parting applications compared to other pentagonal inserts currently on the market. Three insert sizes are available for parting: .787, 1.181 and 1.575 inch diameters.

The new Dove IQ Grip Tiger Line of tools and inserts were also created for deep heavy grooving. The line features very rigid dovetail clamping, a user-friendly locking mechanism with frontal access, unobstructed chip flow (no upper jaw or screw cavity) and a wide variety of standard sizes in the .394 –.787 inch range.

The Tang-Grip IQ line consists of tangentially clamped single-ended inserts for face grooving. The same insert can be used for both right and left hand tools. The combination of tangential clamping and free chip flow results in very high reliability and improved tool and pocket life.

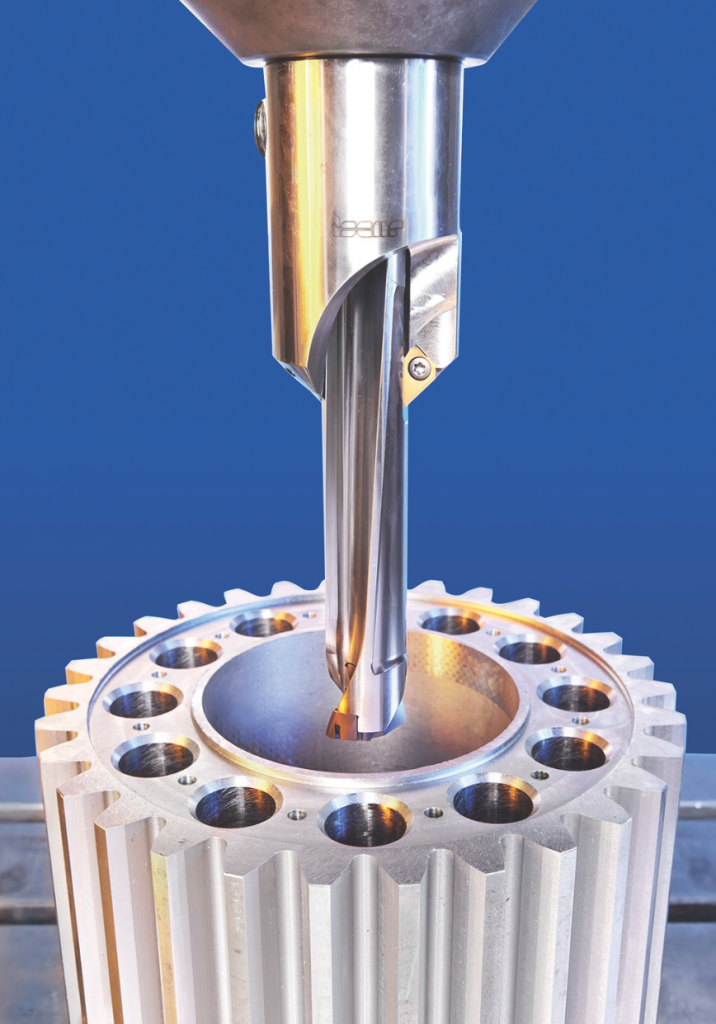

Iscars new Sumo Unicham. Click to enlarge. (Photo: Iscar)

The Dove IQ Mill 845 line of inserts boast a unique design, complete with eight reinforced cutting edges for a wide range of 45 degree face milling applications, roughing and finishing operations on a wide variety of materials. The inserts also feature wiper flats for high surface finish and innovative rake face geometry for optimal chip formation.

Other highlighted products included the Sumo Unicham, a DCNS modular drill without a flange, to be used in chamfering operations with the company’s existing Chamring modular chamfering drill holders. Combining the advantages of existing Sumocham drills with those of the Chamring, the Sumo Unicham can chamfer around holes in a diameter range of .295 to 1.020 inches and L/D ratio of 3xD and 5xD. The projection of the Sumo Unicham inserted into the Chamring can be adjusted for drilling depths in blind and through-hole applications for the standard 30 degree, 45 degree and 60 degree chamfers by using XCGT inserts. The new drill uses standard Sumocham ICP/K/M/N drilling heads.

Harpaz also introduced the Sumogun drill line for deep drilling applications of a diameter range of .472 – 1.0 inch (total length of 60 inches). The Sumogun deep drill line features two straight flutes with a standard Sumocham head. The head’s design enables the Sumogun drill to run at faster table feeds when compared to common gun drills on the market. The Sumogun also has the ability to clamp different heads according to the material and application type.

Harpaz’s presentation at the Living Arts Centre ended with a folksy anecdote about African wildlife.

“Every day the gazelle knows it will have to run faster than the lion it doesn’t matter [however] if you are a lion or a gazelle, when the sun comes up, you’d better be running,” read a series of slides depicting bucolic nature scenes.

“We have the right product line to help you run fast,” added Harpaz.