Visitors check out the supersized CELOS model and new design of a DMG/Mori NLX machine. Click to enlarge. (Photo: DMG/Mori)

DAVIS, Calif. – DMG/Mori has announced positive attendance numbers from its inaugural Manufacturing Days event, at their factory in Davis, California.

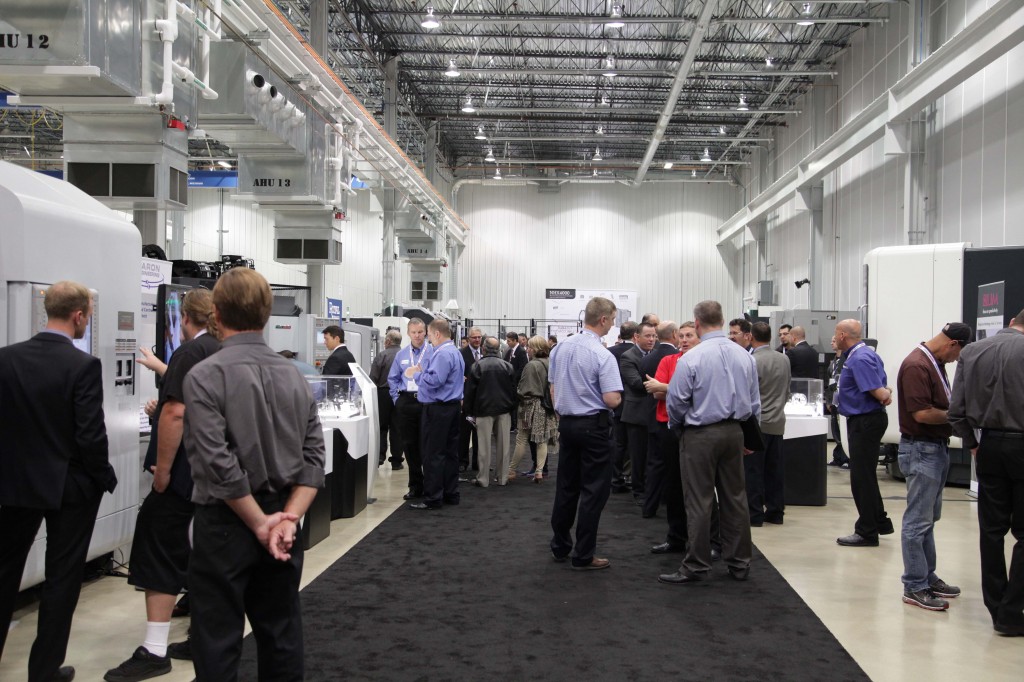

The four-day, November 12-15, event brought more than 1,300 visitors through the company’s U.S. manufacturing facility and the adjacent Digital Technology Laboratory (DTL). The Open House event provided attendees with a look into the 200,000-square-foot manufacturing facility, as well as educational seminars and live cutting demos.

The event also included personal facility tours, showcasing current production of horizontal and vertical machining centres for North America.

“Since opening DMG/Mori Manufacturing in July of 2012, we wanted our customers and distributors to get the opportunity to spend time in the new facility and learn about how our machines are made,” says DMG/Mori USA President Mark Mohr.

RELATED: DMG/Mori Seiki USA host grand opening of new facility

“While our annual spring event, Innovation Days, will continue to show our customers what’s new and innovative, Manufacturing Days Davis’ focus is more on seeing behind the curtain and learning how our machines are developed—and how we continue to improve the applications.”

Dr. Masahiko Mori, the company president, was also on hand to give an outlook on the future of manufacturing, as well as the ongoing process of the merger between DMG and Mori Seiki.

Dr. Greg Hyatt, Chief Technology Officer, introducing a paradigm shift in additive manufacturing; this new approach combines laser metal deposition with five-axis CNC milling

Carl Bass, President & CEO of Autodesk, speaking on innovation, and specifically what makes a company truly innovative and what areas of manufacturing can really change the way things are made in this age of access, information and experience

Visitors in the full exhibition area in the DMG/Mori Manufacturing facility in Davis. (Photo: DMG/Mori)

The Open House also marked the North American introduction of CELOS — a new interface that simplifies and accelerates production processes through integrated management, documentation and visualization of job, process and machine data. It is compatible with PPS- and ERP-systems and also can be linked to CAD/CAM software.

“We’d like to thank everyone who attended Manufacturing Days Davis this year and we look forward to this being a reoccurring event,” says Adam Hansel, CTO of Digital Technology Laboratory (DTL).

“We are proud of the facility and the work being done here and hope all attendees left with a true understanding that our machines are of the highest quality.”

To learn more visit: www.dmgmori.com