SST Consumables Group introduces a new wire, optimized for use on Makino machines with HyperCut technology, including the U3 and U6 wire EDM machines. Together, the wire and HyperCut technology provide superior part accuracy, exceptional surface finish and drastic reductions in cycle time.

SST Consumables Group introduces a new wire, optimized for use on Makino machines with HyperCut technology, including the U3 and U6 wire EDM machines. Together, the wire and HyperCut technology provide superior part accuracy, exceptional surface finish and drastic reductions in cycle time.

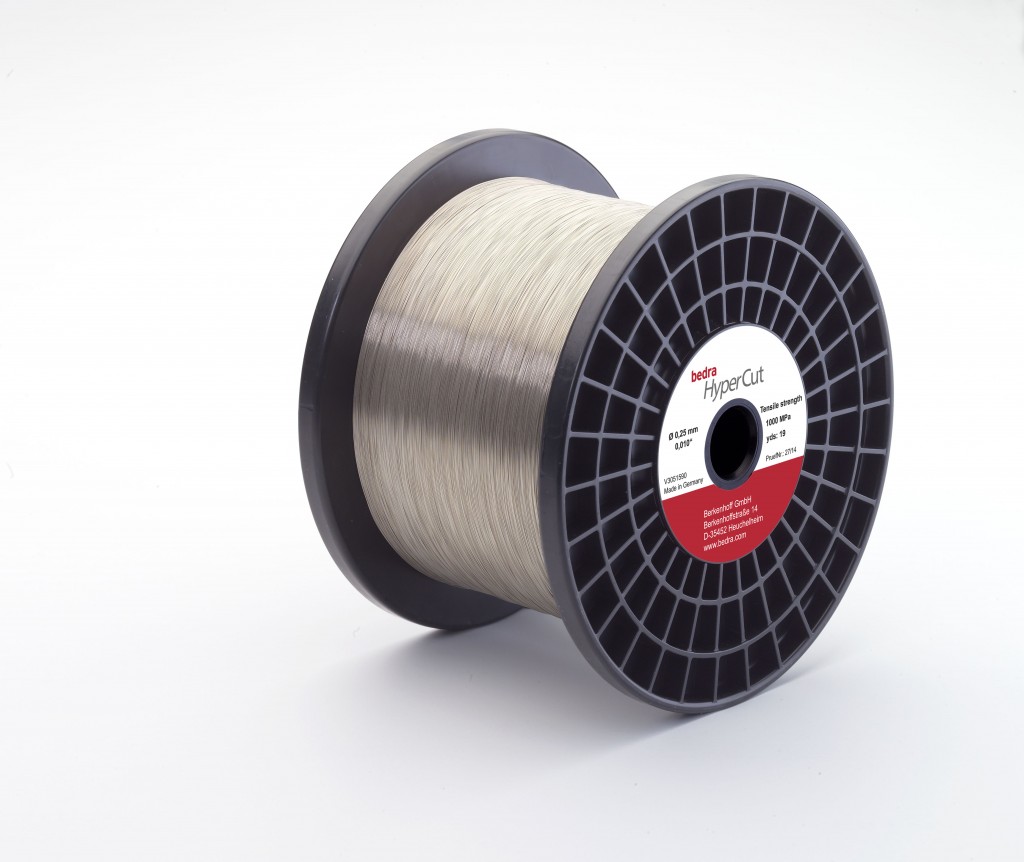

This wire technology is a result of collaboration between Makino and Bedra. Bedra has 125 years of experience in wire manufacturing and is highly regarded for being a pioneer in the development of high-performance, high-precision coated EDM wires. The company smelts, draws and coats its own materials in-house, enabling it to achieve 100 percent process control.

The HyperCut wire boasts high cutting speed, excellent precision and surface quality on Makino machines with HyperCut technology. Initial results of tests using this wire have seen machining speeds increase by as much as 20 percent compared to standard brass wire.

The core material of the HyperCut wire is brass (CuZn40), with an outer coating of gamma-phase brass and a tensile strength (MPa) of 900. This wire offers superior auto-threading and cleanliness. It is available in 0.008-, 0.010- and 0.012-inch diameter on P5, P10, B8 and B16 spools purchased from SST.

For more information, visit www.singlesourcetech.com.