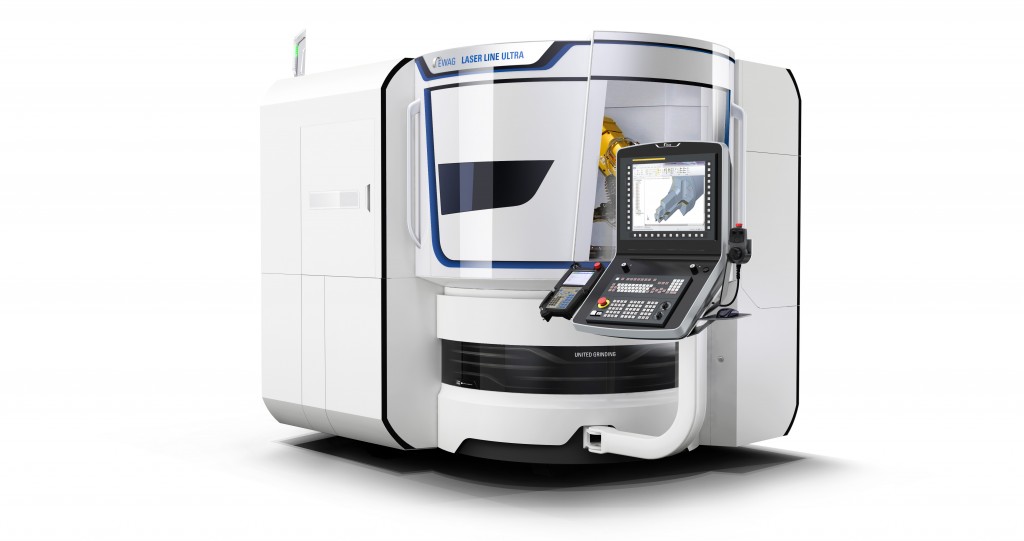

UNITED GRINDING has extended its line of WALTER EWAG technologies for cutting tool production to now include the LASER LINE ULTRA 5-axis machining center that incorporates ultra-short pulse laser technology.

With this new tool-machining system, tool makers can efficiently meet increasing demands for high-precision CVD-diamond tooling needed to cut today’s challenging materials such as lightweight carbon fiber (CFRP) and special aluminum alloys.

With this new tool-machining system, tool makers can efficiently meet increasing demands for high-precision CVD-diamond tooling needed to cut today’s challenging materials such as lightweight carbon fiber (CFRP) and special aluminum alloys.

The LASER LINE ULTRA production center uses a unique kinematic concept that combines a 5-axis machine kinematic system (X/Y/Z/B/C) with superimposed 3-axis laser beam guidance (U/V/W). The design allows toolmakers to laser machine a tool’s cutting edges as well as laser ablate its complex step chipbreakers in one machine clamping. The ultra-short pulse laser technology directly vaporizes materials without significant heat input and without comprising their integrity.

The machine offers an X/Y/Z travel of 15.74 x 7.09 x 5.91 (400 x 180 x 150 mm) and a high-precision tool holding fixture (C-axis) that can be equipped with mechanical or vacuum clamping systems for plate-shaped tools. The C-axis is also available with a fully automatic HSK63 interface for processing rotary tools with maximum cutting diameters up to 5.91 (150 mm).

EWAG encapsulates and protects the LASER LINE ULTRA’s fully integrated 50W high-power picosecond laser beam path so as to protect it from external influences. The laser source and relevant optical elements are integrated into the system’s water-cooling circuit and guarantee the highest possible process stability. An integrated extraction unit extracts laser vapors and flue gases into and through a filter system.

An integrated 6-axis articulated-arm robot with triple gripper head automatically loads the LASER LINE ULTRA for autonomous production. The machines robot cell comes standard equipped with two pallets.

The entire LASER LINE ULTRA system only requires 16.4 square feet (5 square meters) of floor space, making it the most compact high-end laser production center available for processing super hard diamond cutting tools.

For more information, visit www.grinding.com.