RÖHMs new LVE and HSFV chuck systems allow manufacturers to quickly and efficiently process long, large pipes as well as associated pipe couplings and connectors.

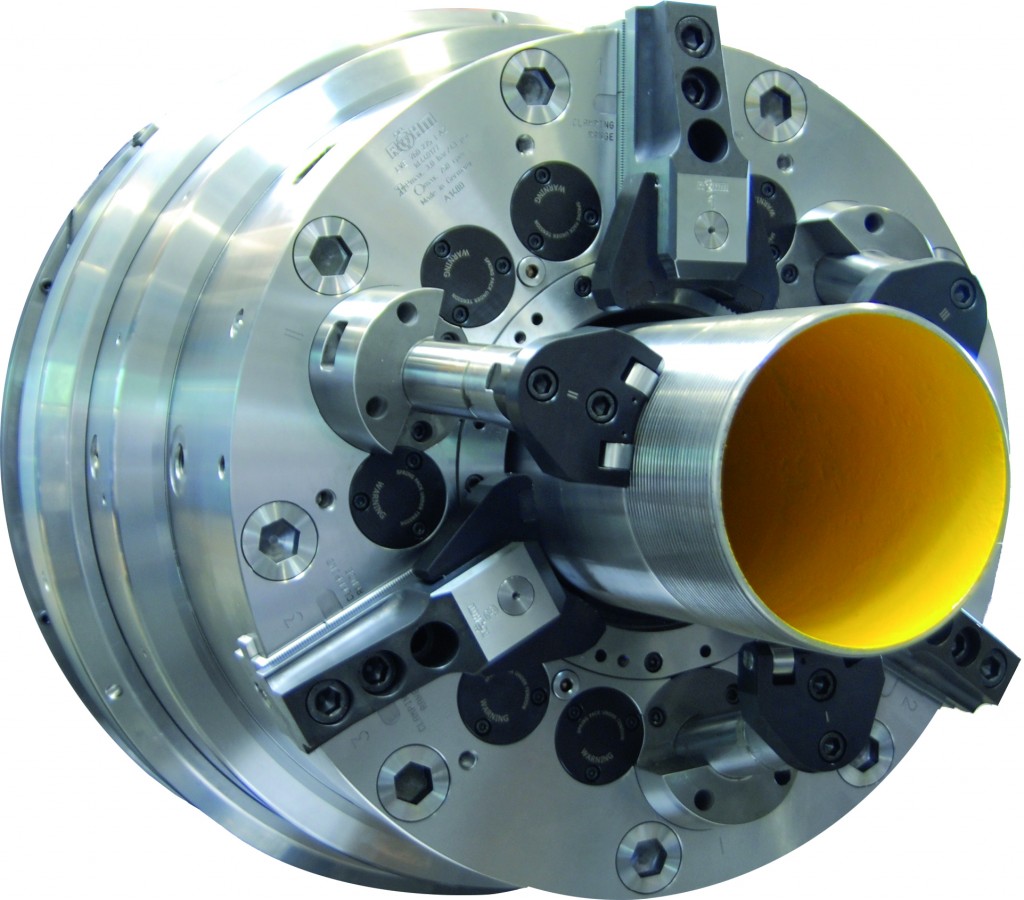

Pneumatic self-contained LVE RÖHM chucks are well suited for machining/threading the ends of pipes, especially those typically used for extracting crude oil or natural gas. For those applications, the chucks can be mounted to the front and rear sides of the machine spindle to allow for heavy-duty chip-cutting performance at high turning precision.

RÖHM LVE Chuck

RÖHM offers the LVE chucks in a variety of configurations to handle a wide range of machining situations such as machining of bent pipe. The configurations include ES versions with rapid stroke and clamping stroke, versions featuring retracting clamping arms for pre-centering the workpiece, and also versions with spring clamping and pneumatic release.

In operation, the chuck’s pre-centering arms extend out around the pipe and center it. Chuck clamping jaws then compensate for any out of roundness in the workpiece shape. An added rear chuck helps drive and further assists in centering long sections of pipe.

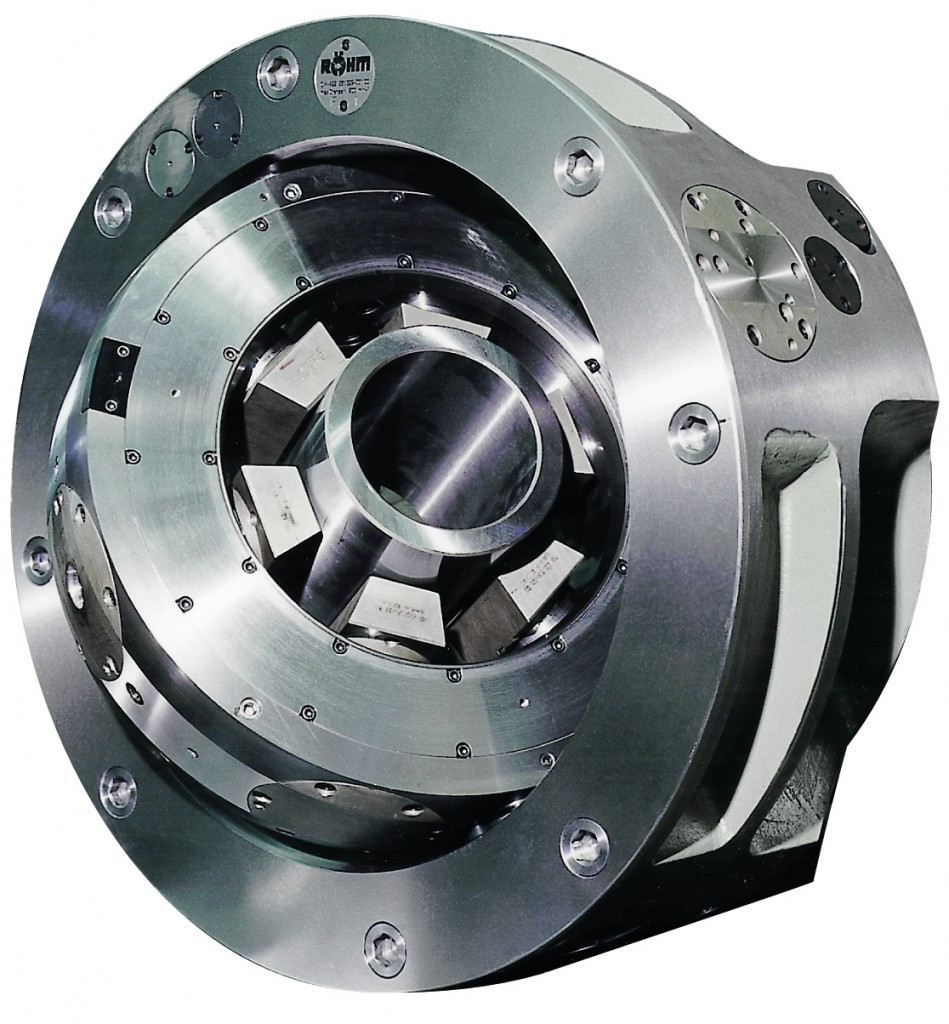

RÖHM Swivel Chuck

For single-setup processing of pipe bushings, couplings and connectors, RÖHM’s HSFZ swiveling chucks clamp parts once and rotate them 180 degrees for complete machining/threading at both ends and on the same centerline. Workpiece rotation cycles are fully automatic and occur while the chuck is spinning. A combination of three concentric clamping jaws with three compensating jaws ensures maximum precision and holding power while also providing low-deformation clamping.

Within its enclosed body, the HSFZ chuck features a swiveling clamping ring actuated by a rack and pinion mechanism. Two tapered bolts at the ring’s outer diameter lock it laterally in place, at 90 degrees relative to the chuck’s rotary axis. Chucks are available in sizes that accommodate workpieces diameters from 2-3/8 (60.3 mm) to 20 (508 mm).

For more information, visit www.rohm-products.com.