Walter has expanded its Tiger·tec Silver range of indexable inserts with three new ISO P geometries, all possessing a positive cutting edge design. These three new products, the FP4, MP4 and RP4, are available with proven WPP10S, WPP20S and WPP30S Tiger·tec Silver cutting grades. The combination of Tiger·tec Silver and the new geometries can result in significant increases in performance. For example, during a recent auto industry field test an MP4 insert made from WPP10S Tiger·tec Silver produced 60 components in comparison to 35 produced with a competing product.

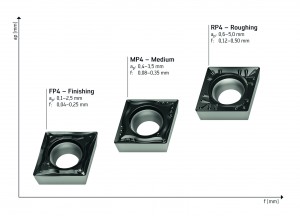

Walter FP4 for finishing, MP4 for medium machining and RP4 for roughing with positive indexable inserts.

The new inserts are aimed at specific applications ranges. The FP4 (F = finishing) is optimized for finishing and achieves the best surface finish quality and chip control for precision machining. The MP4 (M = medium) for mid-range machining with a wide feed rate range with good chip control. It is the most universal design of the three new inserts and is particularly well suited to machining materials such as structural steel or other low-carbon steels. Both the MP4 and FP4 geometries have been optimized for short chip breaking, which is very effective on long-chipping materials such as structural steels. The MP4 geometry is available with two clearance angles 7° and 11°. The clearance angle of 11° enables machining of smaller diameters with lower tool pressure especially for thin wall or delicate components. Finally, the RP4 (R = roughing) offers a highly stable cutting edge for roughing forged steel parts or cast iron. This insert is an ideal choice for high volume machining.

Laser engraving of cutting material type, radius and geometry data reduces the risk of using the wrong inserts.

The positive cutting edge design can offer numerous benefits, such as lower cutting pressures and a lower force cutting action for machining smaller diameters or very long, unstable components. wher these attributes are desirable, a positive cutting edge makes good economic sense. On multi-spindle machines, for example, users can achieve higher feed rates thanks to the reduced cutting pressure and at the same time benefit from excellent chip control.

With Walter’s new FP4, MP4 and RP4, information such as the cutting tool material, radius and geometry which previously could only be found on the indexable insert packaging, is now also laser engraved on the side of each individual insert. This helps minimize the risk of machine operators mixing up the inserts.

For more information, visit www.walter-tools.com/us.