Delcam will highlight developments in PowerMILL and PowerSHAPE at the Windsor Mold Expo in Windsor, ontario on October 23, 2014 at the Ciociaro Club.

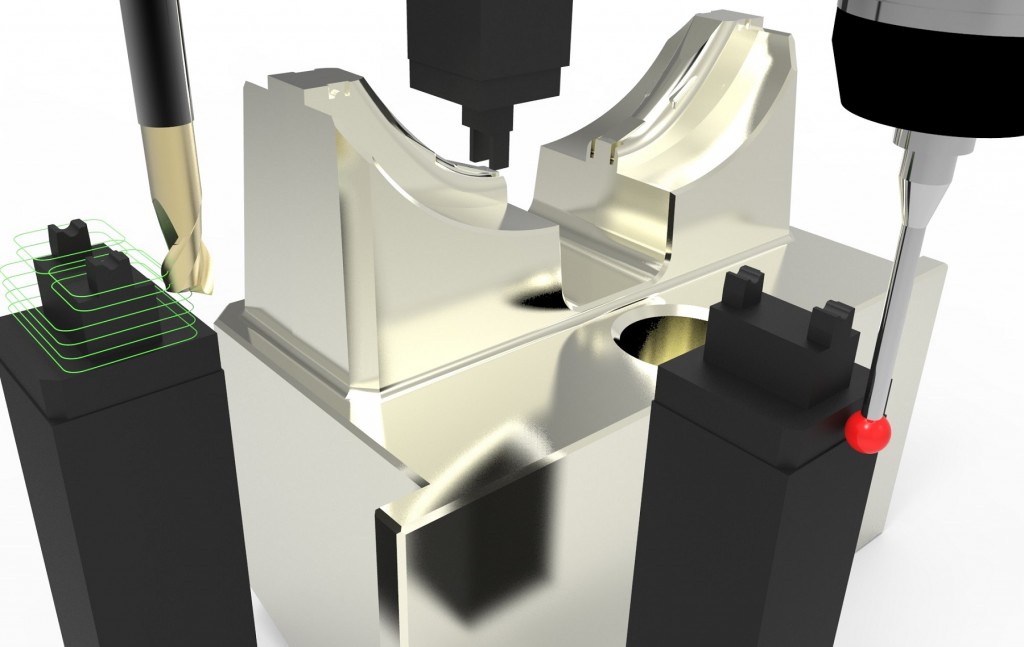

Delcam Electrode provides a complete system for the design, manufacture and inspection of electrodes

By offering a combination of solid, surface and direct modelling, together with reverse engineering functionality, PowerSHAPE Pro provides the most comprehensive range of design techniques available in a single CAD program. Having all the different technologies in the same package reduces the need to transfer data between multiple programs and so streamlines the whole product development process.

The main enhancement in the 2015 release is the Smart Feature selecor. This option allows multiple similar features to be found and selected using either a specific value or a range of values. once the particular group has been selected, all the features within it can be edited simultaneously.

This new functionality will speed the preparation of models for manufacturing significantly. For example, one common problem in product designs that are to be moulded or cast is that fillet sizes are set so small that they restrict the flow of material. The Smart Feature Selector can be used to identify any fillets below the required radius and then all the fillets found can be increased to the desired minimum size simultaneously.

The new release of PowerMILL, Delcam’s programming system for high-speed and five-axis machining, includes improvements to the Vortex high-efficiency area-clearance strategy, expanded collision checking to also cover near misses, and more efficient raster finishing.

Another program that has seen significant development is the Delcam Electrode integrated solution for the design, machining and inspection of electrodes. In particular, data management has been simplified with the option to output an electrode schedule from the software. The data can be output in HTML, Excel or CSV format as a table describing each electrode required and its key data, such as blank size, undersize value, material etc. This option will, of course, be of most value when large numbers of electrodes are required in a project, for example, for a complex mould tool.

Delcam Electrode combines functionality from PowerSHAPE, PowerMILL and PowerINSPECT to give a completely integrated solution for the design, machining and inspection of electrodes. At the heart of the solution is a unique file format – the .Trode file. This contains all the information for each electrode project, including not only the electrode design but also the machining and inspection information, plus the set-up sheets for its manufacture and use. Having all the required information in a single file simplifies data management as well as increasing overall efficiency.