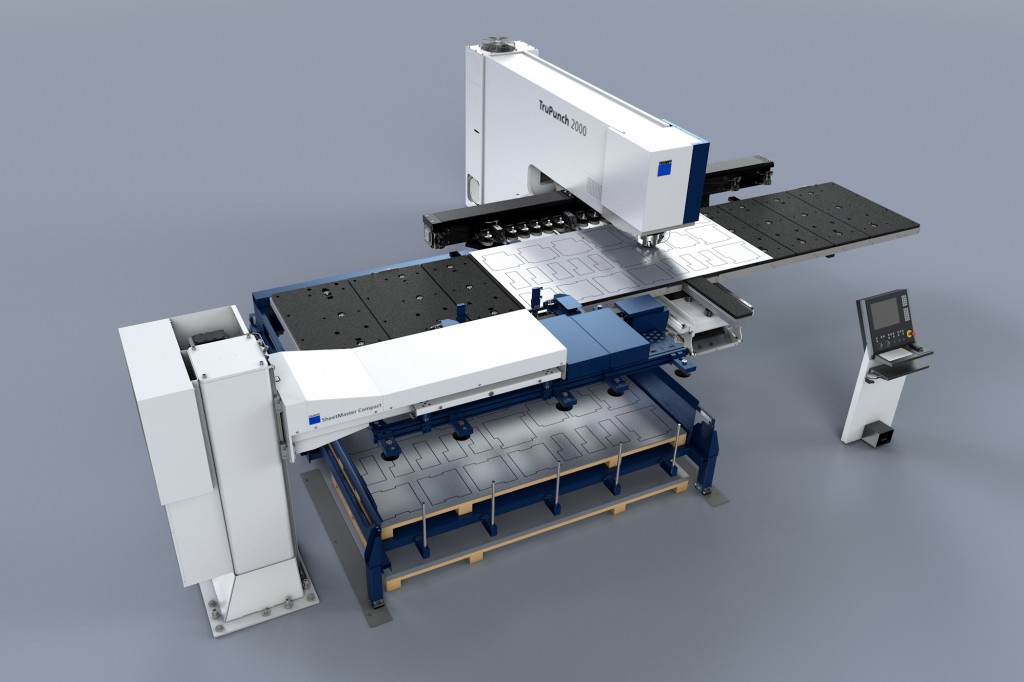

TRUMPF will introduce the TruPunch 2000 with SheetMaster Compact to the North American market in booth B1903 at FABTECH. The event takes place at the Georgia World Congress Center in Atlanta, GA, November 11-13, 2014. Featuring an innovative on-demand drive technology, the hydraulic system only runs when the punch head is active, minimizing the energy consumption of the machine and the load on the system. The machine features a 50 in. x 100 in. working range and can process material up to 0.250 in. thick.

As part of the TruPunch product portfolio, fabricators also profit from TRUMPF’s high standards in punching performance, including impressive axes speeds, high maximum stroke rates, and short setup times. With full 360° tool rotation and tabbed sheet automation capabilities, the TruPunch 2000 is flexible as well as accurate. The machine is controlled by a user-friendly touch screen interface which graphically displays the program and all essential information – keeping operators in control, regardless of their experience level. These and other features make it the ideal choice for fabricators in need of productivity and process reliability at a competitive investment and operating cost.

As part of the TruPunch product portfolio, fabricators also profit from TRUMPF’s high standards in punching performance, including impressive axes speeds, high maximum stroke rates, and short setup times. With full 360° tool rotation and tabbed sheet automation capabilities, the TruPunch 2000 is flexible as well as accurate. The machine is controlled by a user-friendly touch screen interface which graphically displays the program and all essential information – keeping operators in control, regardless of their experience level. These and other features make it the ideal choice for fabricators in need of productivity and process reliability at a competitive investment and operating cost.

TRUMPF’s SheetMaster is the central element for automated loading and unloading of material. The small footprint of the SheetMaster Compact enables automated processing, even when floor space is limited.

For more information, visit www.us.trumpf.com.