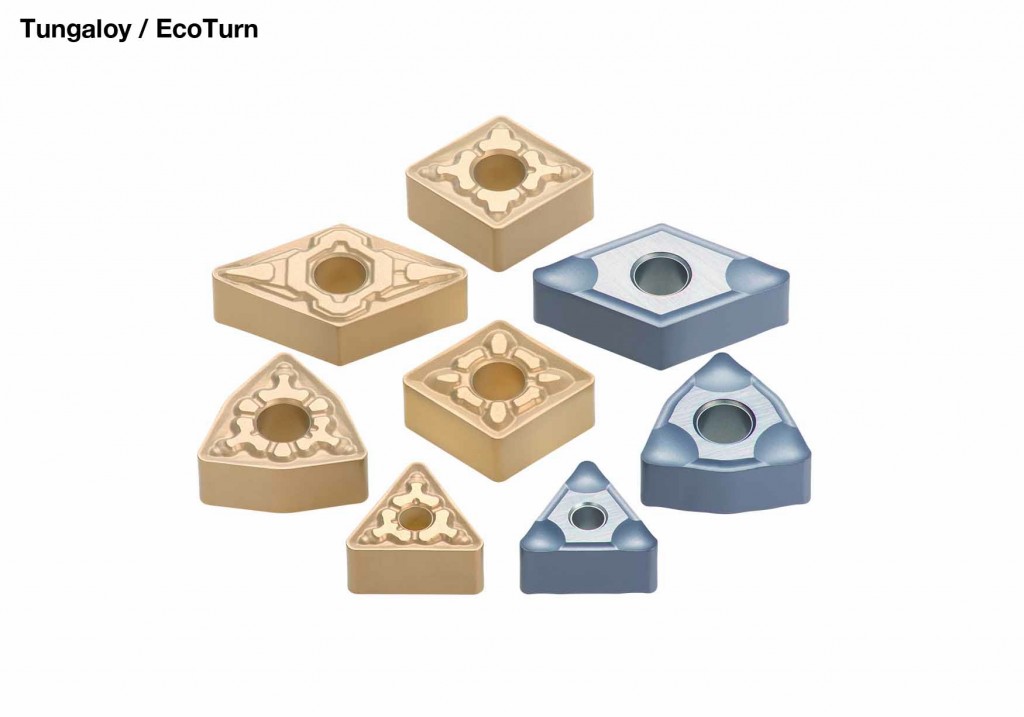

Tungaloys EcoTurn line

Tungaloy has developed a new range of turning inserts. The new EcoTurn line is a series of inserts that are dimensionally smaller than standard ISO insert ranges, meaning they are more economical, and use less resources than standard size inserts.

The new series incorporates the same chipbreaker designs as Tunagloys turning lines with identical insert thicknesses for enhanced strength.

The new ISO turning line offers exceptional economy by reducing the tooling cost per insert corner when machining at depths of cut up to 3 mm.

The EcoTurn series is available with CNMG, DNMG, TNMG, WNMG insert forms and the grades on offer include the Tungaloy T9115 and T9125 CVD coated inserts for steel machining. For finish turning, the NS9530 Cermet and GT9530 coated Cermet grade with its exceptional fracture resistance is the insert of choice.

The line has been created to generate improved profit margins for end users through reduced tooling costs.The chipbreakers include Tungaloys TSF, TM, SS and SM types. These chipbreaker designations give the end user a choice of inserts for finishing to medium cutting applications for all four of the insert forms on offer.

To accommodate the new EcoTurn range of inserts, Tungaloy has expanded a series of “Turning A” toolholders that utilize double clamping design to increase clamping forces and rigidity.

The double clamping system improves stability and cutting performance while the newly designed position of the clamping reduces chip adhesion and thus enhances chip-flow away from the work envelope.

The new toolholders are available for right or left hand cutting in metric and imperial dimensions and combining with the insert types. The EcoTurn range is suitable for turning, facing and profiling processes.