Tungaloy has extended the their TungCut product line with new insert grades.

Tungaloy has extended the their TungCut product line with new insert grades.

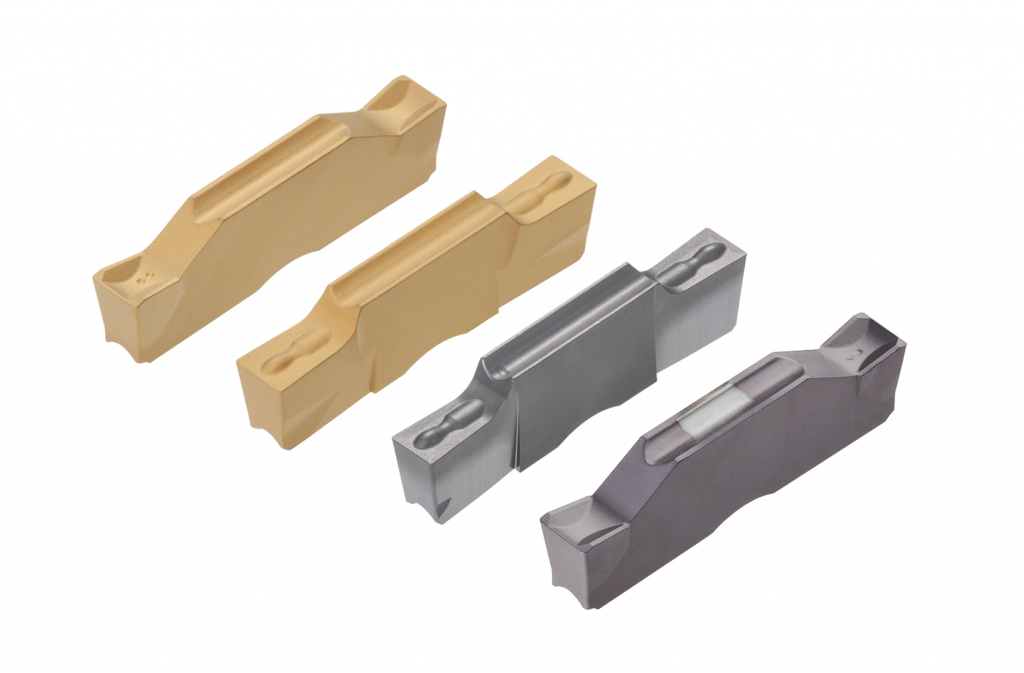

The toolholders and insert geometries will now be further enhanced with a new T9125 CVD coated grade for machining steel at high speeds, a new AH905 PVD grade for machining superalloys and a new NS530 Cermet grade for delivering surface finishes when cutting steel.

The multi-function grooving system that offers grooving, parting, traversing, profiling and undercutting has now been extended to offer a greater variety of standard items that can reduce tool changeovers and the associated costs of non-cutting times.

The new CVD, PVD and Cermet coatings will now be available with all the existing insert designations and geometries to extend the capabilities and performance of the existing lines.

The new T9125 CVD coating gives current product lines enhanced chipping resistance with stable tool life. Incorporating Tungaloys adhesion reinforcement technology the T9125 will improve the performance of the existing geometries when cutting steel at high machining speeds.

Alongside the T9125 is the new PVD coated AH905 insert grade. Ideal for machining heat-resistant alloys, the new AH905 incorporates a new (Al,Ti)N coating for extending tool life that optimises oxidation resistance, toughness and wear resistance when cutting superalloys.

For enhancing surface finishes, the Tungaloy Corporation is adding its new NS530 grade to the TungCut range. It is suitable for high speed cutting of steel, due to its balance of wear resistance and toughness.