Click here to go Flying with laser article.

Bystronic

Bystronic

Bystronic’s BySprint Fiber 3015 is a high power fiber laser cutting machine based on the BySprint Pro platform and the concept ByVention Fiber laser machine. The BySprint Fiber 3015 marks the company’s first production series model of a laser cutting system that employs fiber laser technology.

Equipped with a 2 kW Fiber 2000 fiber laser, the BySprint Fiber 3015 is powerful enough to cut steel, stainless steel, aluminum, and non-ferrous metals, such as copper and brass, with high process reliability and precision. It offers what the company claims is unparalleled performance with thin metal sheets that range up to .160-in. thickness, and the laser source provides power enough to process sheet materials as thick as .500-in.

The laser beam is transported to the cutting head through a passive fiber, as opposed to the deflection mirror systems employed by carbon dioxide lasers. The result is lower operating and maintenance costs, in addition to significant energy savings as a result of using the Fiber 2000 laser source. The laser cutting system offers fast cutting speeds and a high degree of system flexibility that job shops require. The cutting head is available in several configurations, with focal lengths of 100 mm and 150 mm. Both the laser source and the chiller are integrated into the equipment control console, eliminating the need for additional floor space.

www.bystronicusa.com

Cincinnati Inc.

Cincinnati Inc.

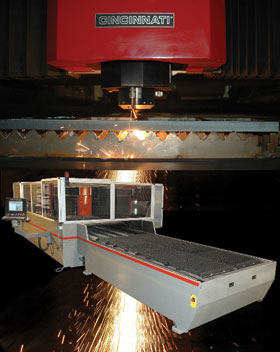

The Cincinnati CL-850 laser cutting centre makes fast work of thick and thin material with a powerful 5000 W GE Fanuc laser resonator, advanced cutting head, innovative optics and third-generation linear motor drive system. It delivers 1000 ipm cutting on 20 gauge steel, and up to 1.125 in. processing range on mild steel. The CL-850 is available in 5 x 10 in. (1.5 m x 3 m) and 6 x 12 ft. (2 m x 4 m) cutting table models, each featuring dual quick-change pallets. Pallets move simultaneously, so changes take just seconds and cutting is virtually continuous. Full guarding and a frame-mounted resonator save shop space over other lasers, claims the company.

The laser cutter’s third generation linear motor drive system makes fast work of large parts or batch processing of smaller parts, while delivering industry-best dynamic positioning accuracy of ±0.001 in. at high cutting speeds.

A next-generation cutting head system gives superior edge quality and comes standard with latest Autofocus head providing 5 in., 7.5 in. and 10 in. (127 mm, 190 mm and 254 mm) focal length lenses. The lenses allow the focus points to be instantly adjusted – especially between piercing and cutting–for optimal processing of various materials. Innovative optical features enhance part quality and improve productivity. An adaptive beam enhancer manipulates the size of the beam to improve piercing and cutting productivity.

The new Cincinnati Modular Material Handling System (MMHS) boosts productivity of CL-800 series dual-pallet laser cutting systems, reducing cost per part and allowing unattended operation for up to three shifts via automated load/unload of raw materials and finished parts.

www.e-ci.com

Hypertherm

Hypertherm

Hyertherm has launched its new fiber laser cutting system that includes all components in one complete package.

Unlike products from many other fiber laser manufactures, Hypertherm’s HyIntensity Fiber Laser HFL015 system includes the power source, cutting head, gas supply, operator interface consoles, motion controls, and software. Hypertherm says this solutions-based approach will make it easier for partners and their customers to use laser cutting for their fine feature cutting requirements.

The system operates on familiar Hypertherm control platforms, with pre-developed cutting processes for simplified table integration and operation, as well as higher levels of efficiency, when compared to other laser cutting solutions. A single-emitter diode based design enables extremely reliable performance.

“Our fiber laser system is unique in that all of the components are engineered and designed to work together.

Cutting application specialists defined and validated all of the cutting parameters so our partners and their customers can easily use laser for a broad range of applications including marking, efficient processing of gauge and fractional materials, and fine feature cutting,” says Doug Shuda, Hypertherm’s fiber laser product manager.

Fiber laser offers several advantages over CO2 laser systems. It requires virtually no maintenance, is more energy efficient, and takes up less space. The power supply is much smaller than CO2, yet

fiber delivery enables the beam to travel greater distances allowing for installation on larger tables.

Hypertherm’s introduction of a fiber laser system follows several years of intense research and development. The company applied more than four decades of metal cutting expertise to develop a powerful system that builds upon Hypertherm’s existing plasma cutting system offerings.

www.hypertherm.com

LVD Strippit

LVD Strippit

LVD Strippit’s Sirius 3015 Plus CO2 laser cutting system is an automation-ready flying optics laser cutting system with efficient processing of parts at optimal speeds and accelerations to suit the part geometry. It offers reliable cutting performance at an affordable price-performance ratio, according to the company. Sirius is offered in a standard and a Plus model. The Sirius Plus is optimized with additional features and automation capabilities.

Sirius provides quick and precise positioning and consistently accurate laser processing. The combination of a dynamic machine with an excellent laser beam quality allows high speed laser cutting. Quick positioning is achieved with axis speeds up to 120 m/min.

The Sirius machine is designed with a modular construction, permitting the user to selec the configuration that works best for the application and budget. As a standard unit, the laser cutting system features 3 m by 1.5 m integrated shuttle tables, which maximize uptime by allowing one table to be loaded while the machine is cutting on the other table. Table change time is 25 seconds.

Sirius Plus is engineered as automation-ready and can be expanded with the addition of various components to form an automated load/unload system. An optional compact tower system creates a productive, flexible manufacturing cell that can be operated “lights out.” The tower system, working in concert with the material handling unit, provides full capabilities for loading and unloading, and includes a shelving unit for storing raw material and finished parts.

Sirius is equipped with a laser cutting head that accommodates a 5 in. or 7.5 in. (127 mm or 254 mm) quick-change lens for fast changeover and minimal set-up.The high pressure cutting head produces exceptionally clean cuts. A crash protection system protects the head from damage after collision with the workpiece. A total power control feature automatically adjusts the laser power in relation to the cutting speed, ensuring an optimal cut at every contour width and minimizing the heat-affected zone. The machine’s edge function feature processes sharp corners cleanly, particularly in thicker materials.

The series employs the reliable Fanuc RF excited fast axial flow CO2 laser. Sirius is available with a powerful 2.5 kW or 4 kW CO2 laser.

The laser, CNC control, drives and motors are fully integrated, providing superior processing speed, high reliability, and low operating and maintenance costs.

The integrated Fanuc PC-based control provides perfect reproduction of programmed contours, producing acute angles at high speed.

www.lvdgroup.com

Mazak Optonics

Mazak Optonics

The Mazak STX RTC 2D laser system is designed to help job shops differentiate and diversify the services they provide.

This machine laser cuts thin to thick sheets of flat material, and also has an integrated rotary chuck to cut tubes and pipes, an extended Z height for cubic components, a standard tapping head and even chamfers, all on a single machine. The rotary table cuts round pipe up to a maximum diameter of 14.76 in., (372 mm) and square tubes up to 6 in. (152 mm). The large 16.14 in. (410 mm) range of Z travel enables you to laser cut preformed parts and other three dimensional shapes requiring greater cut height.

The STX Mark III RTC is available in 2,500 W (0.75 in. mild steel) or 4,000 W (1 in. mild steel) watt configurations and accepts up to a 5 ft x10 ft sheet of flat material. It can be delivered with a large range of automated material handling systems including Load/Unload Cells and Flexible Manufacturing Systems.

www.mazakoptonics.com

Mitsubishi Laser

Mitsubishi Laser

The new higher wattage 4.5 kW resonator for 2D lasers from Mitsubishi Laser replaces the former standard 4.0 kW resonator. This power upgrade will increase output, keeping customers productive and profitable.

The Mitsubishi cross-flow resonator technology reduces rise time/fall time of square wave pulse. This enables more consistent beam power during the cutting process and delivers a more brilliant and consistent edge quality. Additionally, the uniform low current discharge provides low-power stability for improved micro-machining and etching.

The company’s patented three axis, crossflow resonator technology is simple, eliminating from its design the expensive quartz glass tubes and turbo blower systems. This simplification not only optimizes cutting power, it requires two to five times less maintenance than other designs, delivering the industry’s lowest cost of operation and ownership.

www.misubishi-laser.com

Prima

Prima

Prima North America has introduced the Laserdyne 430 multi-axis laser system.

The Laserdyne 430 is a three axis system designed for precision cutting, welding and drilling two and three dimensional components. The new laser cutting system is available with a fourth rotary/circular axis option; a fifth tilt axis will be available this year.

The laser cutting system operates at speeds up to 800 in./min in the X, Y, Z axis (0-20 m/min) with bidirectional accuracy of 0.0005 in. (12.7 micrometer). This accuracy is throughout the system’s 600 x 400 x 500 mm work envelope, making it ideal for processing a broad range of components such as precision drilled fuel filters, electronic assemblies, and transition components at the highest rates with precision quality.

The unit features the company’s latest and most powerful system controller, the S94P. The laser cutting system includes the full complement of the company’s hardware/software features wher required, with features such as BreakThrough Detection (BTD) and a patented Automatic Focus Control (AFC).

www.prima-na.com

Salvagnini

Salvagnini

The revolutionary Salvagnini LiXe fiber laser, acheived its first wide-spread reception at Fabtech 2009.

based on Salvagnini’s proven L1X architecture, the L1Xe is a totally new kind of laser cutter for metal fabrication that reduces cost per part by 50 per cent. With only one mirror, no gas consumables, no turbine, no glass tubes and no moving parts the L1Xe is a model of simplicity and efficiency. All made possible by the latest in fiber optic technology from IPG Photonics.

The L1Xe system is built for speed and performance:

• 60-100 per cent faster than CO2 lasers

• 70 per cent less power consumption

• Cost per part reduced by 50 per cent

• No laser gasses required

• Virtually maintenance free

• Able to process reflective materials such as brass and copper

• Space efficient

• Economical to buy and own

www.salvagnini.com

TRUMPF

TRUMPF

TRUMPF’s new generation of the TruLaser 3030 combines innovative technology and high laser power with a new design concept and optimized operation.

Now available with up to 6 kW of laser power and TRUMPF’s RotoLas tube cutting option, the TruLaser 3030 with the single head cutting strategy sets the standard for the future with features that increase productivity and flexibility when cutting sheet thicknesses up to1 in.

The machine’s long X axis works with a maintenance free gearless torque motor while Y and Z axes are driven by wear-free and oil-free linear motors, which increase the simultaneous axis speeds from 3346 in/min to 5512 in/min (85 m/min to 140 m/min). The FastLine process, now a standard feature, generates a flow transition between the piercing and cutting processes, which reduces processing times by an average of 20 per cent in thin sheet.

The result of the innovative technology found in the TruLaser 3030 is that a greater number of parts can now be cut in the same amount of time as before. Another result is that the power usage per part is reduced, making the TruLaser 3030 an excellent example of energy efficient productivity. The laser also contributes to the machine’s energy efficiency. When it is not cutting, the laser turns into an optimized standby mode until it is needed again. This leads to an energy savings of more than 10 kilowatts as soon as the machine is not in cutting mode.

The TruLaser 3030 also offers a high degree of flexibility during set up.

The pallet changer can be configured in the traditional format or in a transverse fashion, making the best use of space available on the shop floor. An advantage of the transverse position is that the operator has a view of the entire process form the control panel. The swivel-mounted control panel features a self-explanatory touch screen and a control system that is designed to meet the goal in as few clicks as possible. Also, all of the machine’s maintenance areas, including the broadened parallel conveyor belt, are made for easy access.

www.us.trumpf.com