One feature in Cimatron E 12 is the new EDM setup environment that can fully control the electrode burning process on any EDM machine as well as enable safe, “lights-out” operation, the company said.(Source: Cimatron)

One feature in Cimatron E 12 is the new EDM setup environment that can fully control the electrode burning process on any EDM machine as well as enable safe, “lights-out” operation, the company said.(Source: Cimatron)Israel – Cimatron has released Cimatron E 12, the latest version of its integrated CAD/CAM software.

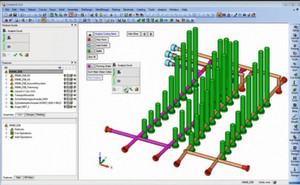

According to the company, Cimatron E 12 provides enhanced tools that can ramp up productivity and minimise overheads in the design and manufacturing of moulds, dies and discrete parts. To meet the challenges of tight delivery deadlines, the supplier has reportedly improved design automation, process management and machine utilisation.

120 years of MM

On the CAM side, Cimatron E 12 has raised the bar with programming efficiency, roughing productivity and finishing quality, the company said. The new NC setup tool lets users define materials, machines and part setup, offering better process management. The new Machine Preview shortens programming cycles by enabling optimisation of multi-axis machine orientation before the toolpath is calculated, Cimatron said. Another new capability is said to enable users to visualise the remaining stock in colour and on the fly, for better decision-making at any point of the process.

Roughing productivity is also said to be enhanced with a highly accurate 3D stock for 3- and 2-axis positioning and 5-axis applications, resulting in safe roughing and reduced machining time. Additionally, better surface quality and longer tool life are claimed to be obtained thanks to the more uniform toolpath, which provides smoother machine motion, and reduced vibrations, the company said. Furthermore, a new rest milling strategy for handling complex geometry with any cutter combinations is said to deliver efficient toolpaths and less machining time.

One of the outstanding features in Cimatron E 12 is the powerful new EDM setup environment that can fully control the electrode burning process on any EDM machine as well as enable safe, “lights-out” operation, the supplier explained. It added that it can be adapted to customers’ in-house methodology, supporting both direct and indirect output file formats.

Mould and die designers will also enjoy a wholly revamped insert design application that automatically creates all standard aspects of the design, saving a lot of time and manual operations, Cimatron said.

Additionally, Motion Simulation now comes enhanced with the ability to conduct valuable dynamic analysis at the very start of a project. A new cooling design and analysis capabilities are said to support both traditionally drilled cooling channels as well as conformal cooling channels made with 3D printing technologies.