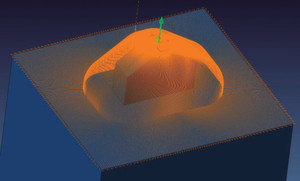

Gallery:1 imageThe electrode module is vital for selecting the proper toolpaths.(Source: Vero Software)

Gallery:1 imageThe electrode module is vital for selecting the proper toolpaths.(Source: Vero Software)UK – British shop Harwin, Portsmouth, works with several Visi software modules on its Gecko brand of micro miniature shock-proof connectors, which withstand extreme temperatures and are used extensively across a variety of industries including motorsport, energy, avionics, satellites and defence.

When a new connector is designed in Pro-Engineer, the data is loaded into Visi 20 for any minor adjustments necessary for tooling purposes. The mould module is used throughout the entire development process, providing a real-time view of how component changes affect the tool design. The company said the module can apply shrinkage based on the polymer database, and the model gets scaled up to the correct size including shrinkage. After that, the analysis capability allows him to create split lines of the actual moulded cavity, which are put into a standard, default mould tool cassette and sub-divided into various inserts, core pins, and other components making up the cavity. When 3D electrode models and items are complete, the data is passed to the shop floor, wher toolpath programs are created with the machining module. It drives a number of units, including two Agietron Hyperspark die-sinkers, three wire EDMs and a Mikron 300 HSM graphite mill.

UK economic growth holds steady, slowing manufacturing sector

Parts for wire cutting are programmed directly from the CAD data by opening the PEPS-Wire module and importing the file from the network server, creating the program offline and loading it into the machine.