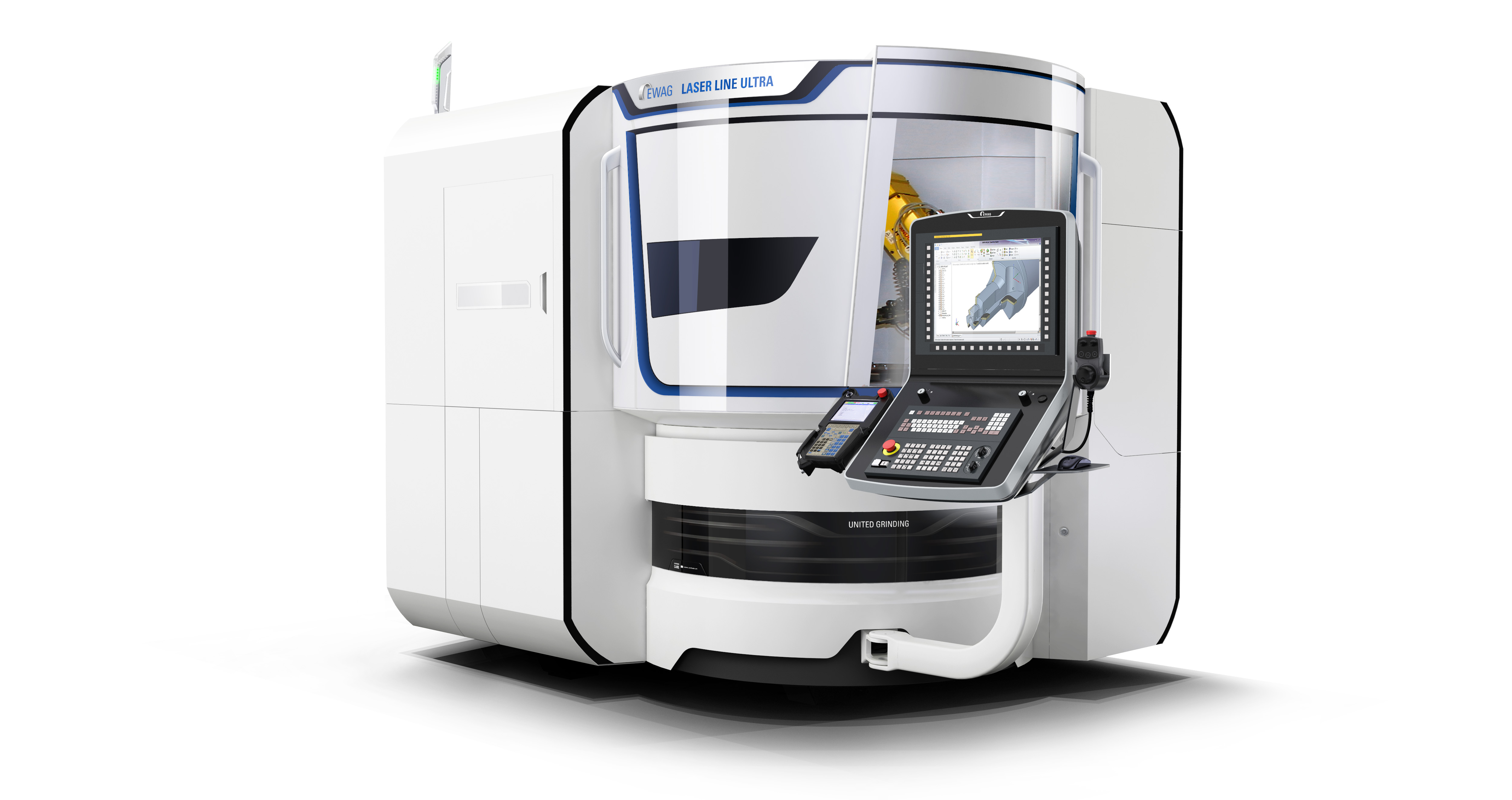

In addition to the existing technologies of grinding, eroding and measuring, laser technology is also covered with the LASER LINE ULTRA from EWAG.

In addition to the existing technologies of grinding, eroding and measuring, laser technology is also covered with the LASER LINE ULTRA from EWAG.

With the development of the LASER LINE ULTRA, EWAG has consistently followed the future trend of modern cutting materials and tool requirements. High priority was given to application flexibility from the outset when developing the LASER LINE ULTRA. A unique kinematic concept was followed, comprising a 5-axis machine kinematic system (X/Y/Z/B/C) with superimposed 3-axis laser beam guidance (U/V/W). This enables laser machining of tool cutting edges as well as laser ablation of complex step chip breakers in a single clamping.

An integrated 3D measuring probe is used for precise calibration of the soldered-in diamond blanks. This equalizes flatness errors from the soldering process and guarantees a precise focus position. The 5-axis machine is equipped with modern, water-cooled direct drives and covers a traversing range in X / Y / Z of 400 x 180 x 150 mm. The tool holding fixture (C-axis) of the LASER LINE ULTRA can be equipped with clamping systems (mechanical or vacuum clamping) for plate-shaped tools. The high-precision C-axis is now also available with a fully automatic interface HSK63 for rotation tools, up to a maximum cutting circle diameter of 150 mm.

The LASER LINE ULTRA is loaded automatically by a standard integrated 6-axis articulated-arm robot with triple gripper head for autonomous production. The machines robot cell is equipped with two pallets as standard. A 50W high-power picosecond laser including laser control and water-water heat exchanger is integrated into the machine structure. The laser control is fully integrated into the machine software. The beam path of the LASER LINE ULTRA is fully encapsulated and protected from external influences in a protective atmosphere under a slight overpressure. The laser source and relevant optical elements are integrated into the water cooling circuit and guarantee the highest possible process stability. The flue gases produced and the evaporated material are extracted very close to the process in the LASER LINE ULTRA thanks to the extraction unit integrated into the machine structure, which conveys them into an extraction/filter system. The entire system only requires a mounting area of 5 m2, making it the most compact high-end laser production center for super-hard tools.

For more information, visit www.ewag.com.